An idea is only as good as the team behind it.

Vape Bot is a creation of British Automation, a UK-based company that develops hardware and software solutions for the retail and hospitality sectors.

We began exploring the concept of vape vending in 2017 when a trend started to emerge toward smaller and more portable devices. We could see the demand shifting toward convenience, with several early models of disposable devices starting to appear.

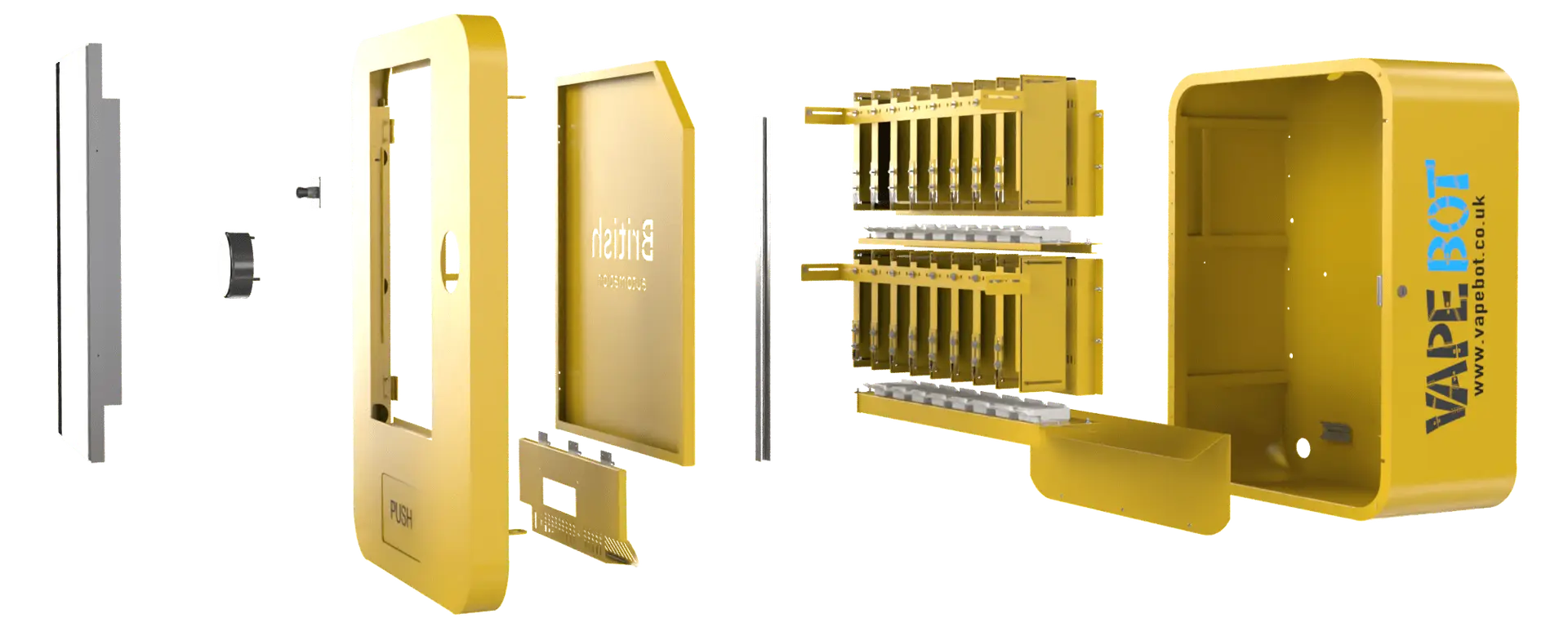

To that end, we began investing in the technology required to retail such products in an “unattended” environment. Everything from the vending mechanism, which must differ significantly from traditional vending machines, to how we would achieve age verification in a manner that would comply with the legislative requirements of our industry.

Finally, after much effort and several less than successful attempts, we launched Vape Bot in 2022, and it has been an immediate success. Find out more about our ongoing journey below.

Where to find us

Unit 135b North Street

Romford, RM1 1ED

United Kingdom

Opening hours

Mon to Fri: 10am – 5pm

Sat: Closed

Sun: Closed

Contact us

+44 (0)1708 380260

[email protected]

November 2017

Seeing a gap in the market for an automated dispensing system, we began a project to develop a vending machine that was specifically designed for the vending of vaping products.

August 2019

We began a six month trial with our first generation of vending machine stocked with a simple vape pen and a variety of e-liquids. The trial ultimately failed as we found that despite the simplicity of the products stocked, a degree of customer service was still required. And as the perfect product did not exist, we shelved the project.

March 2021

Disposable vaping products started to gain in their popularity and we recognised that these products might be suitable for a vending application. We revived the project, redesigned the machine from the ground up and began exploring possibilities for a fresh trial.

August 2021

We conducted a trial with a large national pub company in 10 pubs and 2 hotels to gauge consumer reaction. It was an immediate success and we began planning for a larger rollout of vending machines.

January 2022

We launched the Vape Bot v2 and installed our first mass-produced unit. Within a matter of days, more locations began to approach us to discuss hosting a Vape Bot vending machine.

April 2022

We rapidly expanded to an estate of 100 vending machines. Aided by the popularity of disposable vaping devices and the benefits delivered to the host locations, we began to organically grow at an exponential rate.

July 2022

Our rapid expansion continued and we saw growth to over 200 installed vending machines by the end of our first two quarters.

January 2023

Battling global shortages and increased lead times, we continue to expand our estate and have grown our estate to over 550 machines.

November 2023

We released the Vape Bot v3 and continue to expand our estate surpassing 800 machines. We also expand our operations to Ireland, France, Spain and Germany.

March 2024

We begin development of the Vape Bot v4 with the aim of designing a vending machine at the forefront of technology and reliability.

October 2024

The Vape Bot v4 is completed and plans begin for its mass-production in our cutting-edge plant in Daventry. We also install our 1000th machine on 24th October 2024.

December 2024

We begin rolling out the Vape Bot v4 as we surpass 1200 machines installed in the UK alone.

ISO Class 7

Every product we manufacture is produced in our ISO Class 7 laboratory which utilises a HEPA filtration systems to maintain air cleanliness, ensuring clean and consistent results.

GMP Certified

Year after year, we have demonstrated regulatory compliance to international GMP standards. As a partner, you can be assured of the strictest standards behind every product that we supply.

ISO Class 9001

As world’s most recognised Quality Management System (QMS) standard, our certification ensures that we have a framework to ensure consistent quality in the goods that we produce.

ISO Class 14001

We are certified as having an effective Environmental Management System to identify, monitor and control potential environmental issues that may arise from our operations.